导航栏

- Home

-

Products

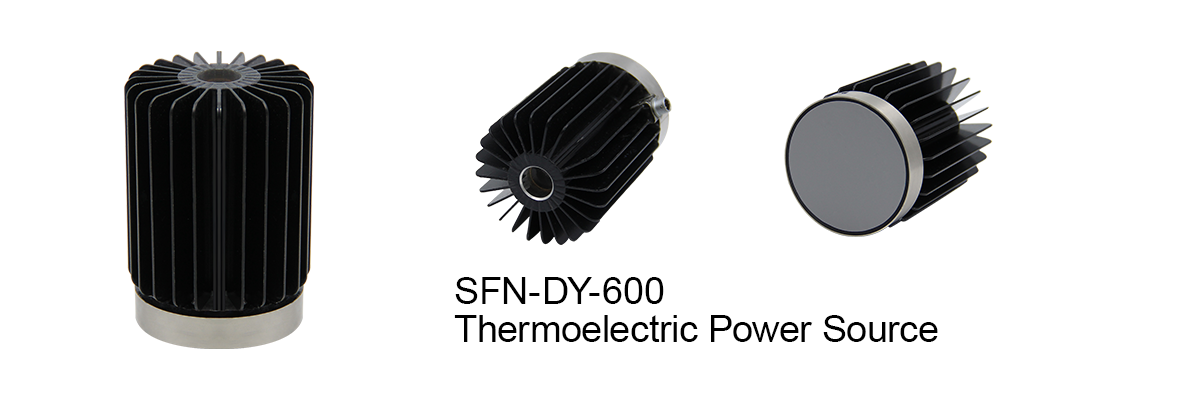

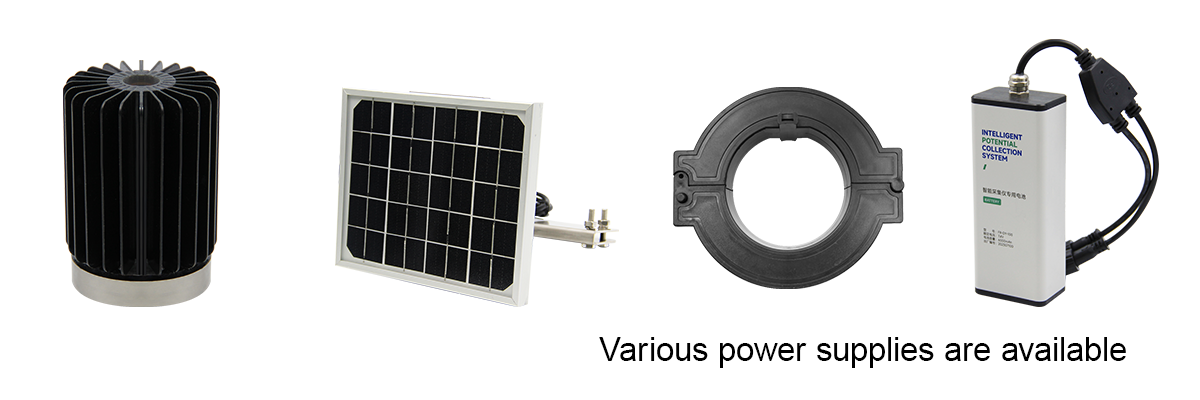

- Self-powered power supply>

-

Self-powered sensors>

- Self-powered dot matrix temperature sensor

- Self-powered temperature and humidity sensor

- Self-powered temperature and vibration sensor

- Self-powered infrared imaging temperature sensor

- Self-powered pipeline pressure sensor (screen display)

- Self-powered pipeline pressure sensor (no screen display)

- Self-powered pipeline temperature sensor (screen display)

- Self-powered pipeline temperature sensor (no screen display)

- Industries&Solutions

- Support

- Company dynamics

- About us